Introduction

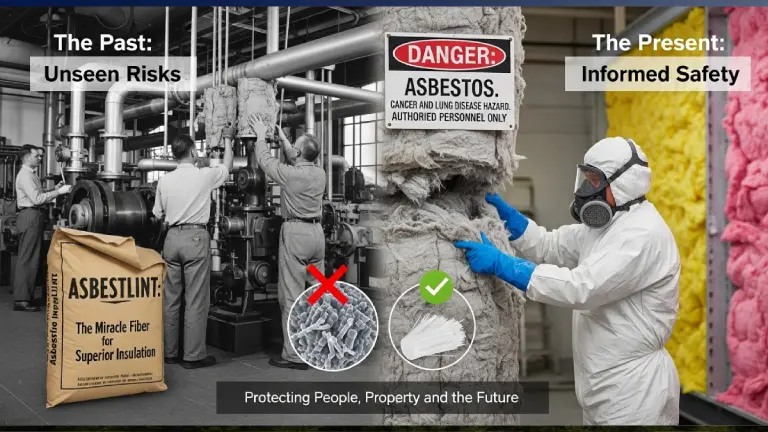

Asbestlint has played a quiet but significant role in industrial history, especially in construction, manufacturing, and high-temperature environments. Once valued for its durability and heat resistance, this material later became known for serious health concerns that changed global safety standards. Understanding its properties, past applications, and current status is essential for professionals, property owners, and anyone dealing with older buildings or equipment. This article offers a clear, practical, and trustworthy explanation, helping you make informed decisions while staying aligned with modern safety expectations.

What Is Asbestlint and Why Was It Widely Used?

Asbestlint refers to a specialized sealing or insulating tape historically produced using asbestos fibers. Manufacturers designed it to withstand extreme heat, pressure, and chemical exposure. These qualities made it popular in environments where conventional materials failed quickly.

Industries relied on this tape for sealing joints, insulating pipes, and preventing heat loss. It performed exceptionally well in steam systems, boilers, and industrial machinery. At the time, durability and performance mattered more than long-term health implications, which were not yet fully understood.

Its fibrous structure allowed flexibility while maintaining strength. This combination explained why engineers and technicians trusted it for decades in demanding conditions.

Common Historical Applications in Industry

The material appeared across many sectors due to its versatility:

-

Construction: Used around heating ducts, expansion joints, and fire-resistant barriers

-

Manufacturing: Applied to machinery exposed to constant heat and vibration

-

Energy facilities: Installed in power plants for thermal insulation

-

Marine environments: Wrapped around pipes and exhaust systems

-

Automotive workshops: Used in brake and exhaust-related sealing tasks

These applications shared a common need: reliable performance under stress. Unfortunately, repeated handling and aging increased fiber release, which later proved dangerous.

Wepbound: The Smart Digital Framework Redefining Online Performance

Health and Safety Concerns You Should Know

As scientific understanding improved, health experts linked airborne asbestos fibers to severe respiratory diseases. When materials containing these fibers deteriorate or are disturbed, microscopic particles can enter the air and be inhaled.

Long-term exposure increased the risk of serious conditions affecting the lungs and surrounding tissues. Symptoms often appeared years later, making early detection difficult. This delayed impact raised major concerns among workers who had frequent contact with the material.

Because of these findings, safety authorities worldwide introduced strict regulations. Many industries phased out older insulation and sealing products, replacing them with safer alternatives.

Regulations and Modern Handling Standards

Today, strict rules govern the handling, removal, and disposal of legacy asbestos-based materials. Only trained professionals using controlled procedures may work with them. Protective equipment, containment measures, and proper waste management are mandatory.

In many regions, using newly manufactured asbestos products is prohibited. Inspections often focus on older buildings and industrial systems where remnants may still exist. Awareness and compliance are critical to avoid legal penalties and health risks.

Comparison Chart: Legacy Tape vs Modern Alternatives

| Feature | Traditional Asbestos-Based Tape | Modern Fiber Alternatives |

|---|---|---|

| Heat Resistance | Extremely high | High to very high |

| Health Risk | Severe if disturbed | Minimal when used correctly |

| Flexibility | Moderate | High |

| Durability | Long-lasting | Long-lasting |

| Regulatory Status | Restricted or banned | Fully compliant |

| Environmental Impact | Hazardous waste | Safer disposal |

This comparison shows why industries transitioned toward safer solutions without sacrificing performance.

Safe Alternatives Available Today

Modern materials replicate the original benefits while eliminating health hazards. These include fiberglass tapes, ceramic fiber wraps, and advanced synthetic composites. They offer excellent thermal resistance, chemical stability, and ease of installation.

Manufacturers also improved adhesive technologies, ensuring better sealing and longer service life. These innovations meet current safety standards while maintaining efficiency in high-temperature environments.

Choosing certified products and following manufacturer guidelines ensures both performance and compliance.

Identifying and Managing Existing Materials

If you suspect older insulation or sealing tape in a building or facility, do not disturb it. Visual inspections alone cannot confirm fiber content. Professional testing provides accurate identification.

When confirmed, risk assessments determine whether encapsulation or removal is necessary. Encapsulation seals the material to prevent fiber release, while removal eliminates it entirely. Each approach depends on condition, location, and exposure risk.

Proper documentation and maintenance planning help reduce long-term liabilities.

FAQs

1. Is asbestlint still found in old buildings?

Yes, it may still exist in older structures, especially in heating systems, industrial plants, or facilities built before strict regulations were enforced.

2. Can damaged insulation tape be dangerous?

Damaged or disturbed material can release harmful fibers into the air, increasing health risks if inhaled over time.

3. How can I safely deal with suspected materials?

Always consult certified professionals for inspection and handling. Never attempt removal without proper training and equipment.

4. Are modern alternatives as effective?

Yes, current materials match or exceed the performance of older products while meeting modern safety standards.

5. Does replacement improve property value?

Upgrading outdated insulation and sealing materials can improve safety compliance and overall asset value.

Conclusion

Asbestlint represents an important lesson in industrial progress, showing how performance-driven solutions must align with long-term health and safety. While it once solved critical engineering challenges, modern knowledge reshaped how industries approach insulation and sealing. By understanding its history, risks, and replacements, you can make informed, responsible decisions that protect people, property, and the future.